|

| Microsite |

| Home Page |

| Company Profile |

| Company News |

| Products Show Room |

| Products News |

| Catalogs & Tech Notes |

| Trade Show Information |

| Web TV |

| Product Alert |

| International Contact |

| Contact Information | ||

|

| Featured Products |

|

Variable Force Spring

Brief:

Constant Force Springs

Variable force spring that does not restricted to Hook's Law for compression springs that the load increases proportionally with stroke. According to your request, you can have a multi-load design. Here are some relations between load and stroke that can be used on specific occasion. The product range from 0.03~0.75mm in thickness and 1~50mm in width.

Brief:

Constant force spring is made by winding the steel strip into a coil which exerts a nearly constant retraining force to resist uncoiling. By comparing the differences between constant force spring and traditional wire springs, the advantages will be obtain as following: To exert nearly constant force during entire extension. Short initial deflection, it means that reaching the rated load at short extension. Long extension capability. The product range from 0.03~0.75mm in thickness and 1~50mm in width.

|

| Product Categories | ||||||||

|

|

||||||||||||||||

Copyrights © 2012 Allitwares Corporation All Rights Reserved.

www.allmetalworking.com is a Division of Allitwares Corporation |

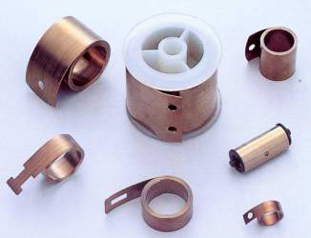

Strip Springs | Constant Torque Spring | Ming Tai Industrial Co., Ltd. |